Better known as Plexiglas®, the methyl polymethacrylate or PMMA has revolutionized the glass industry.

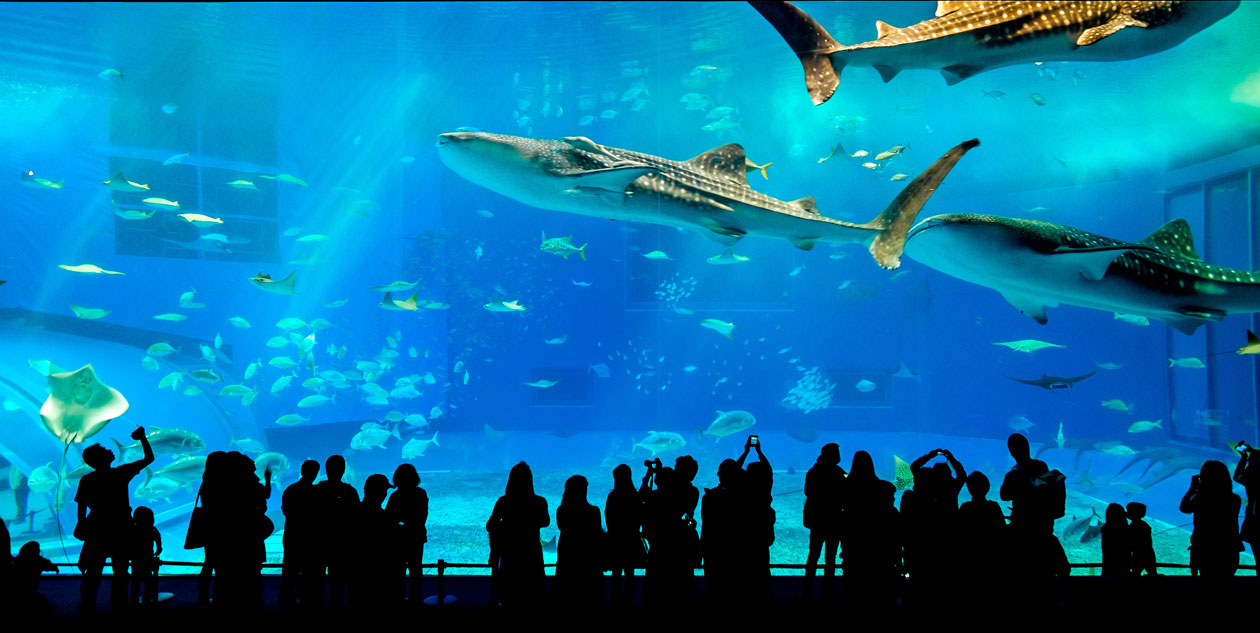

The transparent acrylic plates are not only adapted to the pools but they can also be integrated into the rehabilitation, architectural or artistic applications, zoos and aquariums, etc…

It is in the form of a porthole onto a room, whole pool walls or walls of gigantic aquarium, this material allows expanding the technical limits of the glass walls.

Using Plexiglas® to perform contemporary pools allows the craziest and most spectacular creations.

STRENGH & WEIGHT

Plexiglas® is 25 times stronger and 63% lighter than an untreated glass.

It is particularly resistant to shocks and outdoors and does not break like glass.

Originally conceived as glazing for aquariums, it can be exposed to extreme mechanical stresses and may contain more tones of water.

TRANSPARENCY

PMMA Plexiglas® panels allow over 92% of the sun’s rays have excellent brightness and no image is deformed in the case of thick panels. Therefore, transparency and cleaning of the panels is much higher than that of glass.

The Plexiglas® never yellowing, the panels are transparent as crystal.

The panels are covered by a 30 year warranty against yellowing.

MANUFACTURING

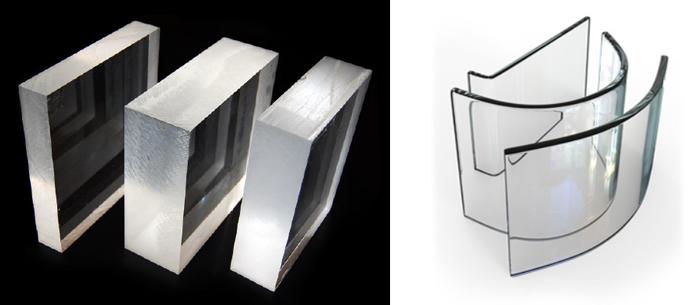

If your project is expected to exceed the standard size, when the standard sizes are not enough, Plexiglas® panels can be welded together without apparent joint.

The maximum size of a standard panel is 7800 x 3000 mm but panels can be welted together to reach bigger dimensions.

Plexiglas® is so versatile that it can be curved (convex or concave). These technical procedures are factory under extremely controlled conditions.

WEATHER CONDITIONS

Plexiglas® is particularly resistant to weathering and UV, as well as solvents and chemicals. It is not sensitive to chlorine nor salt.

The panels have no condensation brands and have a good insulating capacity.

DIMENSIONS

Sensec Europe works with standard panels, 3000 x 2000 mm to 7800 x 3000 mm. The thickness of the panels is calculated according to the project and can range from 20 to 700mm thick.

MAINTENANCE

Plexiglas® surface is perfectly smooth. Dirt can’t be embedded.

The scratching and surface damage can be easily repaired by polishing.

In cooperation with Evonik, world leader in the manufacture of Plexiglas®, Sensec Europe designs and builds each project following the technical requirements of our engineering department.

Sensec Europe offers products for customized, unique, indoors or outdoors projects.

For each project, we calculate the thickness of the panels according to the depth and expansion factors and integrate these technical requirements into reinforced concrete structures that support these windows.

Although very similar, Plexiglas® has many advantages over glass:

- Plexiglas® is about 25 times stronger and 63% lighter than an untreated glass.

- Plexiglas® is more shock resistant and safer than glass.

- Plexiglas® is lighter than glass having a green color.

- Plexiglas® holds more heat than glass.

- Plexiglas® is more versatile than glass. With our technology and our experience of union, thermoforming and bending panels, Plexiglas offers unlimited design potential.

- Plexiglas® is very easy to polish scratch if, unlike glass.

- Plexiglas® is resistant to chemicals.

- Plexiglas® is cast in one piece while the glass wall is generally formed by several layers separated by PVC sheeting.

Plexiglas® thickness varies from 20mm to 700mm depending on the depth and pressure which the panel is subjected to.